Release: CNC machining companies have revolutionized the manufacturing business by providing detail and effectiveness in the generation of varied equipment parts. With assistance from advanced technology and computer-aided applications, CNC machining has transformed into the go-to option for organizations that need supreme quality equipment parts.

In this article, we shall explore what CNC machining companies are and their benefits.

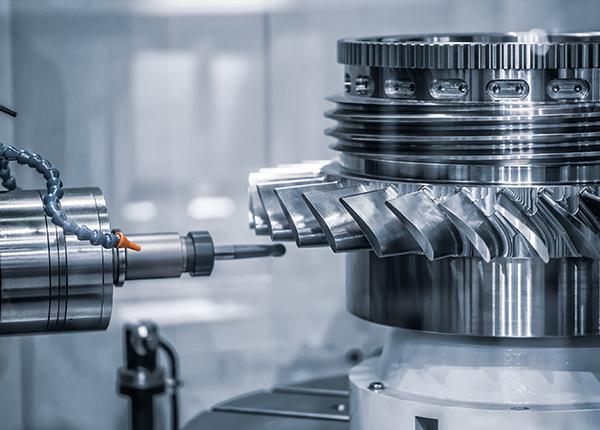

What is CNC Machining? CNC stands for Computer Numerical Control. CNC machining involves the utilization of computer-aided style (CAD) and computer-aided manufacturing (CAM) application to manage the function of machines. These machines include lathes, mills, routers, grinders, and other equipment used in manufacturing.

CNC machines are programmed to follow unique recommendations for producing accurate parts. The software provides the machine with data such as the sizes, form, and substance of the part. The machine then follows these recommendations to create the part with a higher level of accuracy and consistency.

Kinds of CNC Machining Companies: There are several kinds of CNC Machining Services, including:

-

CNC milling – This requires chopping and drilling employing a spinning instrument to create complicated styles and contours.

-

CNC turning – This requires rotating a part on a lathe and chopping it to the desired shape.

-

CNC drilling – This requires drilling holes and other styles into components such as for example steel, plastic, and wood.

-

CNC running – This requires employing a running wheel to form and end materials.

Benefits of CNC Machining Companies: CNC machining companies present several advantages, including:

-

High Accuracy – CNC machines can make components with a top amount of accuracy, creating them well suited for industries that need detail engineering.

-

Performance – CNC machines may generate components quickly and consistently, reducing lead times and increasing productivity.

-

Freedom – CNC machines may utilize a wide selection of components, including steel, plastic, and timber, providing usefulness in manufacturing.

-

Cost-effective – CNC machines are cost-effective in the long term because they reduce labor prices, reduce problems, and improve generation efficiency.

Realization: CNC machining companies have become an important part of modern manufacturing because of the detail, effectiveness, and flexibility. Whether you'll need a simple part or a complicated portion, CNC machining companies may help you obtain the desired results. Therefore, if you are searching for reliable and appropriate machining companies, consider investing in CNC technology for the business.