Para-aramid fibers, often referred to as "miracle fibers," are no strangers to strength and resilience. These high-performance synthetic fibers boast a remarkable combination of properties - exceptional tensile strength exceeding steel, impressive flame retardancy, outstanding chemical resistance, and remarkable resistance to abrasion and impact. This unique blend of characteristics makes them irreplaceable in critical applications where safety, performance, and durability are of paramount importance.

A Market on an Upward Trajectory

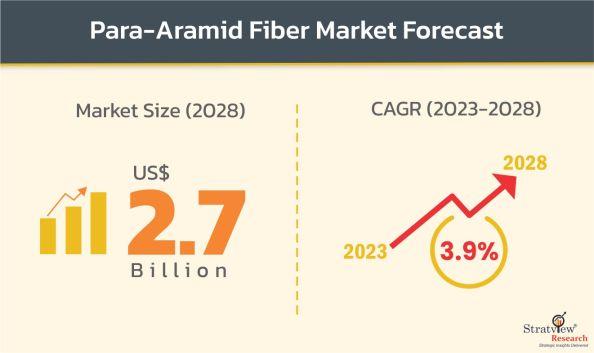

According to Stratview Research, the global para-aramid fiber market size is projected to reach USD 2.7 billion by 2028, growing at a CAGR of 3.9% during 2023-2028. This robust growth is fueled by several key factors:

- Safety Taking Center Stage: The increasing emphasis on safety across various sectors is driving the demand for personal protective equipment (PPE). From construction sites and fire emergencies to law enforcement situations, para-aramid fibers play a vital role in firefighter turnout gear, bulletproof vests, and other critical PPE. Their ability to absorb and dissipate significant amounts of energy ensures the safety of the wearer in potentially life-threatening situations.

- Fortifying National Defense: Geopolitical tensions and a focus on national security are leading to increased investments in military and defense equipment. Para-aramid fibers are instrumental in creating ballistic protection for soldiers, body armor for vehicles, and other military applications. Their lightweight nature allows for improved mobility without compromising protection, a crucial factor in modern warfare.

- Lightweighting the Future: The automotive and aerospace industries are constantly striving for lightweight materials to enhance performance and fuel efficiency. Para-aramid fibers, with their high strength-to-weight ratio, are finding increasing use in aircraft components, automotive parts, and racing car tires. This not only reduces overall vehicle weight but also translates to improved fuel economy and reduced emissions.

- Industrial Evolution and Expansion: Beyond their traditional applications, para-aramid fibers are making inroads into various industrial applications. Their high thermal stability and chemical resistance make them suitable for conveyor belts, gaskets, and filtration systems in demanding industrial environments. This allows for extended equipment life and improved operational efficiency in harsh industrial settings.

Applications Unlocking the Potential of Para-aramid Fibers

The exceptional properties of para-aramid fibers unlock a vast array of applications across various industries. Here's a closer look at some of the key drivers:

- Personal Protective Equipment (PPE): As mentioned earlier, para-aramid fibers are the material of choice for firefighter suits, bulletproof vests, cut-resistant gloves, and other essential PPE. Their remarkable strength and heat resistance provide a critical layer of protection for personnel working in hazardous environments.

- Composite Reinforcement: Para-aramid fibers are often combined with other materials like resin to create lightweight, high-strength composites. These composites find extensive use in aircraft components, boat hulls, and sporting goods, offering exceptional strength and rigidity at a minimal weight. This allows for improved performance and maneuverability in various applications.

- Tire Reinforcement: Para-aramid fiber reinforcements are becoming increasingly popular in high-performance tires for enhanced durability and puncture resistance. This is particularly beneficial in racing and off-road applications where tires are subjected to extreme stress and potential hazards.

- Electrical Insulation: Due to their excellent dielectric properties, para-aramid fibers are used for electrical insulation in cables, transformers, and other electrical components. Their ability to withstand high temperatures and electrical currents makes them ideal for demanding electrical applications, ensuring safety and preventing electrical breakdowns.

- Construction Materials: Para-aramid fibers can be integrated into ropes, cables, and building materials to enhance their strength and resilience. This is particularly relevant in earthquake-prone regions or for structures requiring high tensile strength. Additionally, para-aramid fibers can be used to reinforce concrete, improving its resistance to cracking and impact.

A Global Landscape of Growth and Opportunity

The para-aramid fiber market exhibits a distinct geographical landscape with key players dominating specific regions:

- Asia Pacific: A Booming Market: This region currently dominates the market, driven by a growing middle class, rising disposable income, and significant investments in infrastructure and defense. China, with its expanding manufacturing sector and growing focus on military modernization, is a major consumer of para-aramid fibers.

- North America: Established and Expanding: The established aerospace and defense industries in the United States contribute significantly to the demand for para-aramid fibers in this region. Stringent safety regulations in various sectors further fuel the market growth, creating a steady demand for high-quality para-aramid fibers.