The manufacturing process of Technical Textiles involves several stages that transform fibers into fabrics with specialized properties to meet specific industrial and functional requirements. This process encompasses various steps, including fiber selection, spinning, weaving or knitting, finishing, and quality control.

The first step is fiber selection, where fibers with specific characteristics are chosen based on the desired properties of the end product. These fibers can be natural, such as cotton or wool, or synthetic, such as polyester or nylon. The selection depends on factors like strength, durability, flame resistance, moisture-wicking ability, or conductivity.

Once the fibers are selected for Technical Textiles, they undergo spinning, where they are converted into yarns. Spinning can be done through different methods like ring spinning, open-end spinning, or air jet spinning, depending on the desired yarn properties and production efficiency.

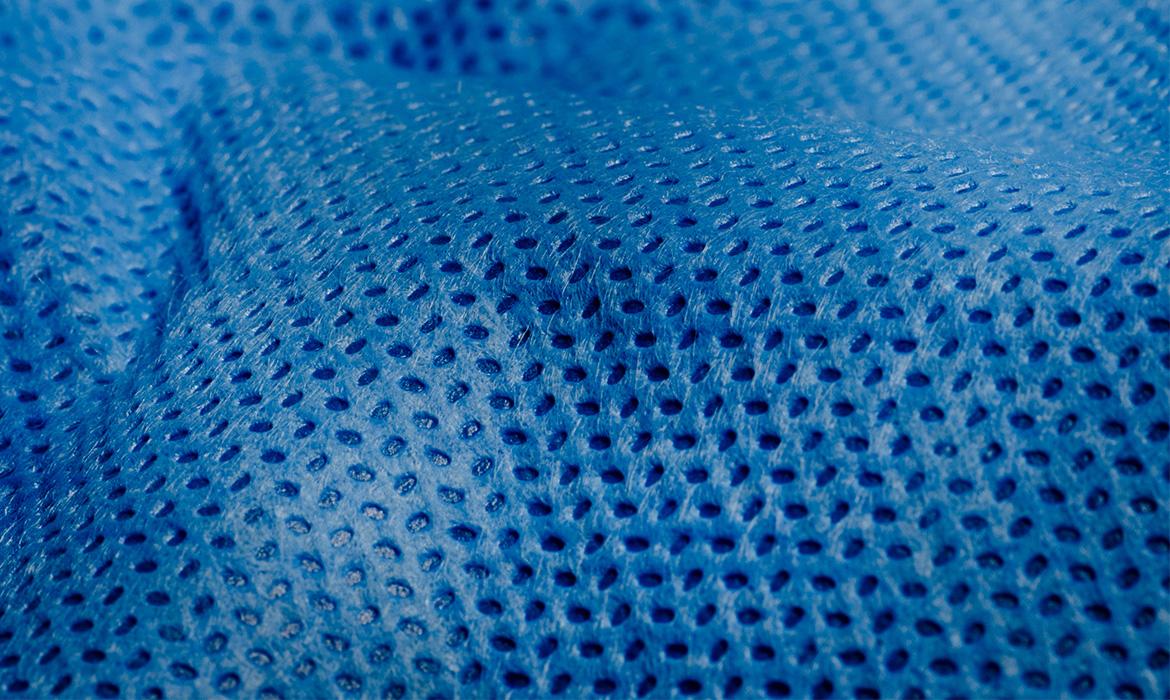

After spinning, the yarns are subjected to weaving or knitting processes to create the fabric structure. Weaving involves interlacing warp and weft yarns perpendicularly, while knitting involves interlooping yarns together. The choice between weaving and knitting depends on the desired fabric characteristics like strength, stretchability, or porosity.

Following the fabric formation, finishing processes of Technical Textiles are employed to enhance specific properties or add functionalities. Finishing treatments can include coating, laminating, calendering, or applying chemical finishes to improve water repellency, flame resistance, antimicrobial properties, or UV protection.

Lastly, quality control measures are implemented throughout the manufacturing process to ensure consistent fabric quality. This involves inspection of fibers, yarns, and fabrics at various stages, testing for strength, dimensional stability, colorfastness, and other performance parameters.

Latex Coating is a method used in the textile industry to provide fabrics with water resistance or flame retardancy by applying a layer of latex onto the fabric surface.

In conclusion, the manufacturing process of Technical Textiles involves fiber selection, spinning, weaving or knitting, finishing, and quality control. Each stage contributes to the creation of fabrics with specialized properties to cater to specific industrial applications, ranging from automotive and aerospace to healthcare and protective clothing.