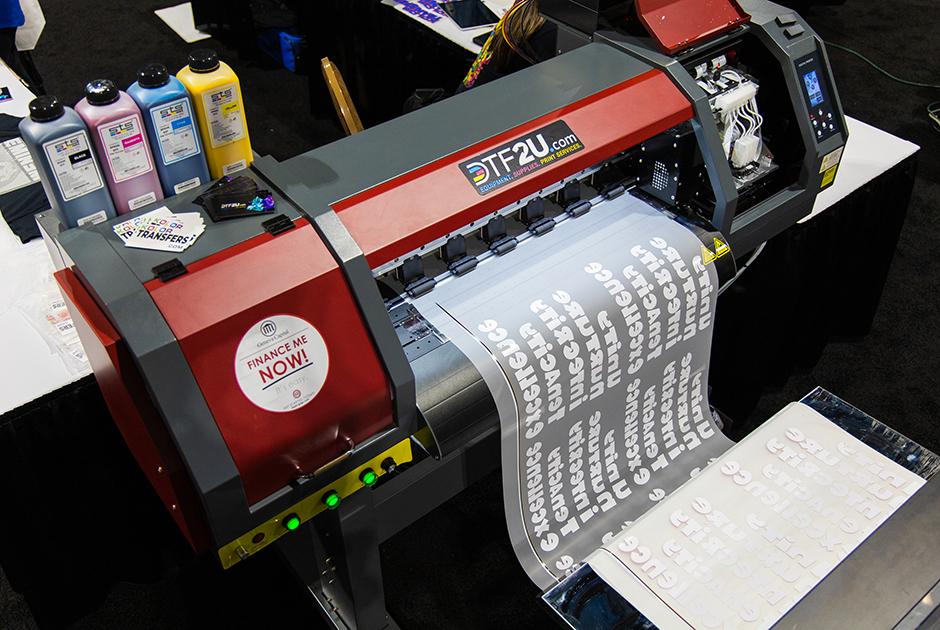

Electronic Textile Picture (DTF) printing is really a revolutionary engineering that's been making waves in the textile printing industry. It offers a flexible and specific strategy for moving high-quality, vivid patterns onto a wide range of materials, opening up new possibilities for modification and creativity. In that exploration, we'll delve into the planet of DTF units, their functions, advantages, and their effect on the textile printing landscape.

DTF printing, also known as Direct-to-Film making, is really a somewhat new addition to the digital printing family. It's a hybrid procedure that includes elements of equally direct-to-garment (DTG) and temperature move printing. Unlike traditional screen printing, which can be labor-intensive and limit the complexity of models, DTF enables complicated and step-by-step design to be printed straight onto textiles with ease.The heart of DTF making may be the specially developed printer and the transfer film best dtf printer for small business .

Making: The design is first printed onto a heat-resistant adhesive picture employing a DTF printer. These models are designed with high-resolution printheads that will reproduce delicate details and vivid colors.Film Transfer: The printed style is then included with a clear, heat-activated film. This film serves as a company that may move the look onto the fabric.

Heat Press: The fabric, with the film-covered design placed on the top, is subjected to temperature and pressure employing a heat press machine. This method causes the printer on the film to sublimate, bonding it with the fabric.Peeling: After a particular period, the film is peeled off, causing behind the produced style on the fabric. The effect is a tough and vivid image that thinks delicate to the feel and doesn't split or fade easily.

Sponsored

Customized Merchandise with DTF Making: From Caps to Hoodies

Posted 2023-09-11 11:52:13

0

61

Search

Sponsored

Categories

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

Read More

Joint Plus CBD Gummies : Reviews (SCAM EXPOSED 2024) Safe or Not? - Joint Plus CBD Gummies Work?

Official Website@>>> https://supplement24hours.com/joint-plus-cbd-gummies-buy/...

Utilizing Artvigil to a Regular Basis – Overview & Advantages

The first thing we need to do is have a look at Artvigil.

Artvigil is a nootropic medication used...

The Benefits of Evergreen CBD Gummies Canada?

➢ Supplement Name:- Evergreen CBD Gummies Canada

➢ Composition — Natural Organic Compound...

Energizing Progress Case Studies from the Frontlines of the Power Rental Industry

Market Overview

The Power Rental Market will acquire a valuation of USD 21.03 billion...

Master Bono Crypto Recovery: Some sort of Beacon connected with Trust with A digital Advantage Clean up

Advantages:

From the ever-evolving surroundings connected with cryptocurrencies, the...

Sponsored